BUENO PFA Lined Valve are suitable for high-corrosive environtment and application

BUENO PFA Lined Valve are resistant against corrosion and guarantee zero leakage. They are widely accepted in semiconductor, optoelectronics, pharmaceutical, food and beverage, petrochemical, refining, biochemical, cosmetics and high purity water industries. We also provide PTFE and FEP lined valve respectively based on customer's request.

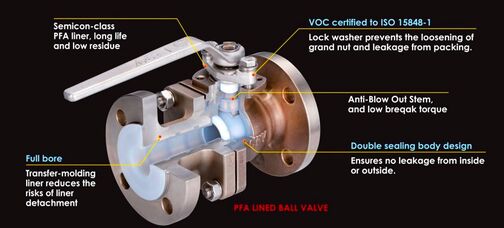

Introducing our cutting-edge PFA lined valve – the epitome of performance, precision, and reliability in fluid control. Crafted with meticulous attention to detail, our PFA lining valve combines the robustness of traditional valves with the chemical resistance of PFA lining, ensuring seamless operation even in the most corrosive environments.

Unleash the power of PFA lining technology, as our valve effortlessly tackles the harshest chemicals and high-temperature fluids. Its innovative design guarantees minimal maintenance and maximizes operational uptime, providing you with peace of mind and cost savings.

Engineered for perfection, our PFA lining valve delivers unparalleled control and durability, making it the preferred choice for industries demanding excellence. Trust in its superior performance to safeguard your processes and elevate your productivity to new heights. Upgrade to the future of fluid control with our PFA lining valve today

►Features of PFA liner

For a number of years, fluoropolymers have played a significant role in the chemical and similar industries, protecting plants and equipments against a wide range of corrosive media. This is due to PFA having substantially better chemical resistance and thermal stability than other engineering plastics. PFA, a perfluoro-alkoxy polymer which has been in successful use for 20 years as a lining material, is now a thermoplastic successor to PTFE. Compare to PTFE, PFA has the equivalent thermal and chemical resistance while superior in processability, translucency, permeation resistance and mechanical strength.

In the chemical industry, PFA is more applied to linings than PTFE because using PTFE is more difficult for the lining of metal parts of complicated shape, such as valves and pumps. PFA material, a thermoplastic material with a well-defined melting point, can be processed through transfer molding to achieve better lining quality.

The granular material is melted in a melt pot and then forced into the hot tool. This transfer molding method makes very precise wall-thicknesses, even at tight radii and in undercuts. In addition, no mechanical finishing is needed, except the removal of sprue and the smoothing of mating faces of flanges. Lastly, the evenness of wall-thickness may vary, especially in the case of a more complicated shape such as valve housings.

►Absorption and Permeation

Different from metals, thermoplastics absorb varying amounts of the media which they come in contact. Absorption may be followed by permeation through the liner. Such problems can be solved by increasing the lining's wall-thickness or installing devices to remove the space between fluoropolymer liner and inner metal wall. It is clear that in terms of resistence against permeation and absorption, PFA, or melt-processed fluoropolymers, is better than PTFE.

►Applicable Areas

1. Highly corrosive non-acidifying acids, such as chloride, sulfuric acid, wet halogen gases, phosphoric acid, acetic acid, and fluoric acid.

2. Fluid transportation systems where there’s interaction between acids and alkalis.

3. Semiconductor and pharmaceutical manufacturing process where organic compound precipitation and metal ion leaching take place.

Introducing our cutting-edge PFA lined valve – the epitome of performance, precision, and reliability in fluid control. Crafted with meticulous attention to detail, our PFA lining valve combines the robustness of traditional valves with the chemical resistance of PFA lining, ensuring seamless operation even in the most corrosive environments.

Unleash the power of PFA lining technology, as our valve effortlessly tackles the harshest chemicals and high-temperature fluids. Its innovative design guarantees minimal maintenance and maximizes operational uptime, providing you with peace of mind and cost savings.

Engineered for perfection, our PFA lining valve delivers unparalleled control and durability, making it the preferred choice for industries demanding excellence. Trust in its superior performance to safeguard your processes and elevate your productivity to new heights. Upgrade to the future of fluid control with our PFA lining valve today

►Features of PFA liner

For a number of years, fluoropolymers have played a significant role in the chemical and similar industries, protecting plants and equipments against a wide range of corrosive media. This is due to PFA having substantially better chemical resistance and thermal stability than other engineering plastics. PFA, a perfluoro-alkoxy polymer which has been in successful use for 20 years as a lining material, is now a thermoplastic successor to PTFE. Compare to PTFE, PFA has the equivalent thermal and chemical resistance while superior in processability, translucency, permeation resistance and mechanical strength.

In the chemical industry, PFA is more applied to linings than PTFE because using PTFE is more difficult for the lining of metal parts of complicated shape, such as valves and pumps. PFA material, a thermoplastic material with a well-defined melting point, can be processed through transfer molding to achieve better lining quality.

The granular material is melted in a melt pot and then forced into the hot tool. This transfer molding method makes very precise wall-thicknesses, even at tight radii and in undercuts. In addition, no mechanical finishing is needed, except the removal of sprue and the smoothing of mating faces of flanges. Lastly, the evenness of wall-thickness may vary, especially in the case of a more complicated shape such as valve housings.

►Absorption and Permeation

Different from metals, thermoplastics absorb varying amounts of the media which they come in contact. Absorption may be followed by permeation through the liner. Such problems can be solved by increasing the lining's wall-thickness or installing devices to remove the space between fluoropolymer liner and inner metal wall. It is clear that in terms of resistence against permeation and absorption, PFA, or melt-processed fluoropolymers, is better than PTFE.

►Applicable Areas

1. Highly corrosive non-acidifying acids, such as chloride, sulfuric acid, wet halogen gases, phosphoric acid, acetic acid, and fluoric acid.

2. Fluid transportation systems where there’s interaction between acids and alkalis.

3. Semiconductor and pharmaceutical manufacturing process where organic compound precipitation and metal ion leaching take place.

Bueno Technology Indonesia supplies all kinds of valve, flow control and industrial automation solution for Indonesia market.

BUENO TECHNOLOGY INDONESIA, a joint-venture company between Indonesian and Taiwanese formed with support of dedicated team with more than 51 years of experience in industrial parts manufacturing is a subsidiary of BUENO GROUP based in Taiwan. Beside of valve and their accessories manufacturing, we offer design and technical capabilities for the manufacture of custom-made machines to meet the needs of our customer and we also offer tooling such as punches, dies, cutters, fingers, pins, and other general forming tools that fit to your production.

BUENO TECHNOLOGY is a versatile manufacturer established in 1969, specializing in providing sophisticated flow control products. We manufacture high-purity, water and oil-free valve, fittings, and components in Class 1000 clean rooms for pharmaceutical, semiconductor, optoelectronic, electrochemical and petrochemical industries, where safety and stability of the manufacturing process are a major concern. Our corporate philosophy if to offer the market innovative PFA lined valves and fitting, PFA tubing, pipes and fittings, conventional valves and parts, PTFE components, lost wax castings, Lost Wax Casting, Precision Casting, plastic products, graphite, spiral wound gasket, and to place the highest priority on safety, long service life, low operation and maintenance cost.

Bueno Technology is one of the renowned manufacturers, suppliers and exporters of PFA Lined Valve, PFA Lined Pipe, PFA Lined Fittings, Stainless Ball Valve, Clean Valve, Threaded Ball Valve, Flanged Ball Valve, Valve Ball, Valve parts, PTFE seat for Valve, Casting OEM, PFA Fitting and PFA Tubing (Tube), with factories in Taiwan, Shanghai and Vietnam. With more than half century of experience in the line of manufacturing, we are known for our outstanding performance in the industry. We have helped ourselves as one of the leading brand in Taiwan. We constantly upgrade our products to meet the international standards. We hold a team of professionals, which provides on time deliveries with high quality. Our sincerity and hard work has helped us match our quality with international standards.

BUENO TECHNOLOGY INDONESIA, a joint-venture company between Indonesian and Taiwanese formed with support of dedicated team with more than 51 years of experience in industrial parts manufacturing is a subsidiary of BUENO GROUP based in Taiwan. Beside of valve and their accessories manufacturing, we offer design and technical capabilities for the manufacture of custom-made machines to meet the needs of our customer and we also offer tooling such as punches, dies, cutters, fingers, pins, and other general forming tools that fit to your production.

BUENO TECHNOLOGY is a versatile manufacturer established in 1969, specializing in providing sophisticated flow control products. We manufacture high-purity, water and oil-free valve, fittings, and components in Class 1000 clean rooms for pharmaceutical, semiconductor, optoelectronic, electrochemical and petrochemical industries, where safety and stability of the manufacturing process are a major concern. Our corporate philosophy if to offer the market innovative PFA lined valves and fitting, PFA tubing, pipes and fittings, conventional valves and parts, PTFE components, lost wax castings, Lost Wax Casting, Precision Casting, plastic products, graphite, spiral wound gasket, and to place the highest priority on safety, long service life, low operation and maintenance cost.

Bueno Technology is one of the renowned manufacturers, suppliers and exporters of PFA Lined Valve, PFA Lined Pipe, PFA Lined Fittings, Stainless Ball Valve, Clean Valve, Threaded Ball Valve, Flanged Ball Valve, Valve Ball, Valve parts, PTFE seat for Valve, Casting OEM, PFA Fitting and PFA Tubing (Tube), with factories in Taiwan, Shanghai and Vietnam. With more than half century of experience in the line of manufacturing, we are known for our outstanding performance in the industry. We have helped ourselves as one of the leading brand in Taiwan. We constantly upgrade our products to meet the international standards. We hold a team of professionals, which provides on time deliveries with high quality. Our sincerity and hard work has helped us match our quality with international standards.