Bueno PTFE & PFA Lined Pipe for long lasting solution for the harsh environment of piping system

BUENO Technology delivers PFA and PTFE lined pipe with our transfer molding process. Transfer molding is a type of molding method that evolved from compression molding; It includes heating and cross linking process which are conducted in two separate locations. Transfer molding begins by melting the plastic material as PFA (Polyfluoroalkoxy/fluoroplymers) in the separation chamber, then injects the material into another sealed mold for it to take shape and harden. When the component being shaped has a complex shape or insert(s), the use of compression molding may damage the component or shift the insert(s). Those possible difficulties can be avoided by choosing transfer molding over compression molding. The equipments of transfer molding can be separated into two categories: pot transfer and plunger molding.

PFA as raw materials and we integrate metal pipe and fitting firmly with PFA by the transfer molding processing. The products not only have the original strength of metal furthermore will also increase its anti corrosive performances. Therefore, application of PFA lined pipe for piping system to comply all kinds of high dangerous chemicals with high temperature and strong corrosion solves issues in the chemical, semiconductor, pharmacy and food industry.

We provide various crucial types of pipe spool and its accessories:

Our metal pipes and fittings for PTFE or PFA lining are either manufactured via casting or through welding seamless pipes.

The available dimensions are 1/2" ~ 6", the thickness of metal pipe and metal fittings for PFA lining are in accordance with schedule 40.

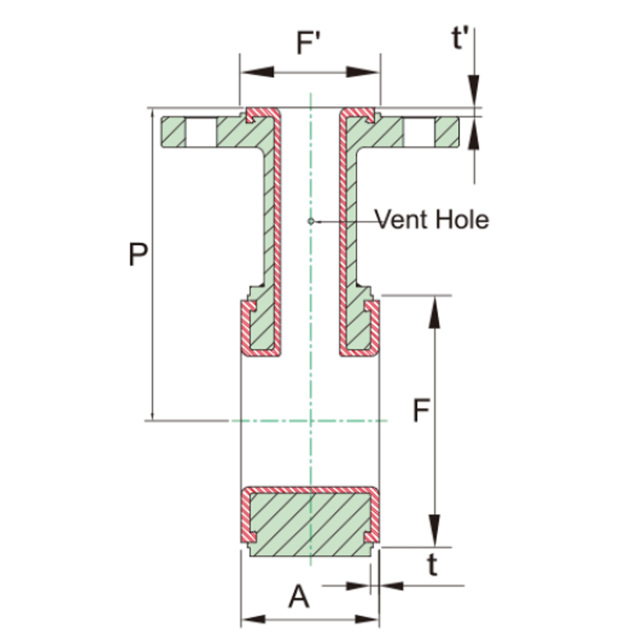

Each PTFE and PFA lined pipe and PFA lined fittings has at least one 2mm diameter exhaust hole in order to release the gast trapped between the liner and the metal part. If the pipe exceeds 500mm in length, it will contain at least two exhaust holes. Reducing flanges don't have exhaust hole.

Applications:

PFA as raw materials and we integrate metal pipe and fitting firmly with PFA by the transfer molding processing. The products not only have the original strength of metal furthermore will also increase its anti corrosive performances. Therefore, application of PFA lined pipe for piping system to comply all kinds of high dangerous chemicals with high temperature and strong corrosion solves issues in the chemical, semiconductor, pharmacy and food industry.

We provide various crucial types of pipe spool and its accessories:

- PTFE & PFA Lined Spools Pipe

- PTFE & PFA Lined Elbow 45°

- PTFE & PFA Lined Elbow 90°

- PTFE & PFA Lined Concentric Reducer

- PTFE & PFA Lined Equal Tee

- PTFE & PFA Lined Reducing Tee

- PTFE & PFA Lined Cross Fitting

- PTFE & PFA Lined Sight Glass

- PFA Spiral Tube

- PTFE & PFA Lined Instrument Connection

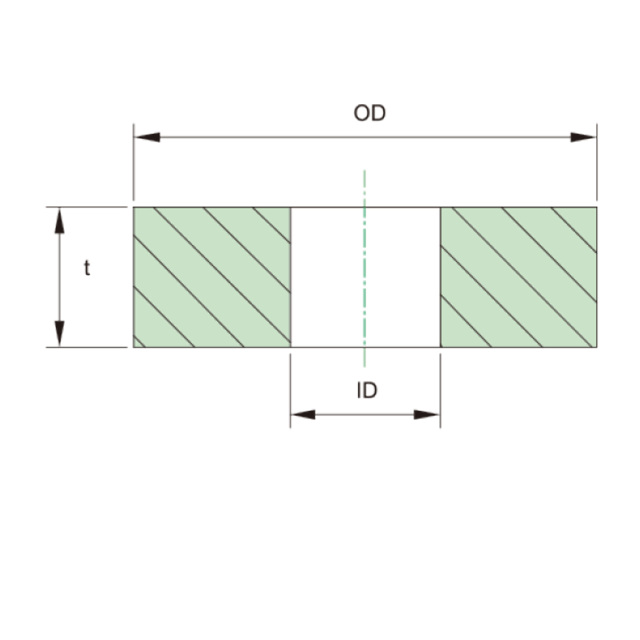

- PTFE Solid Spacer

- PTFE & PFA Lined Blind Flange

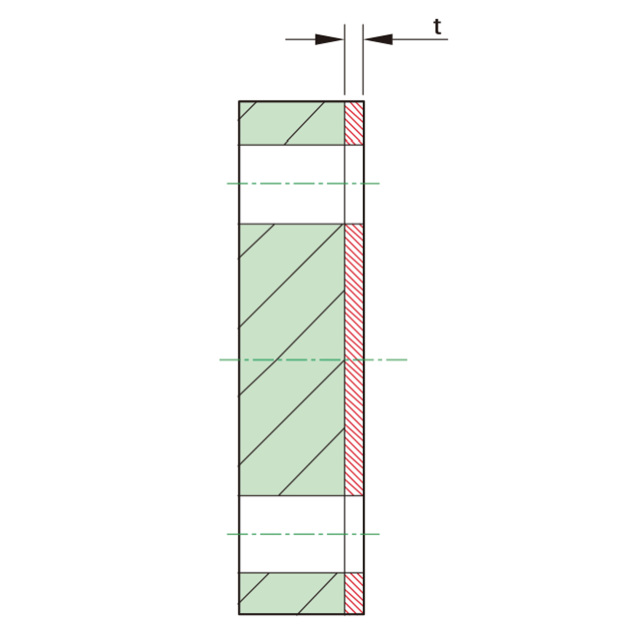

- PTFE & PFA Lined Armored Spacer

Our metal pipes and fittings for PTFE or PFA lining are either manufactured via casting or through welding seamless pipes.

The available dimensions are 1/2" ~ 6", the thickness of metal pipe and metal fittings for PFA lining are in accordance with schedule 40.

Each PTFE and PFA lined pipe and PFA lined fittings has at least one 2mm diameter exhaust hole in order to release the gast trapped between the liner and the metal part. If the pipe exceeds 500mm in length, it will contain at least two exhaust holes. Reducing flanges don't have exhaust hole.

Applications:

- Chemical processing line

- Chemical engineering piping

- Waste water treatment

- Power generation

- Ultrapure chemical processing

- Treatment processing for acids, caustics, bleach